Custom Synthesis of Agrochemical Impurity & Metabolite Reference Standards

FB Pharmtech are highly experienced in the custom synthesis of impurity and metabolite reference standards for use in agrochemical testing, registration and research.

Impurity Reference Standards for GLP 5 Batch Analysis

Process impurities formed during the manufacture of agrochemical actives are required to be identified and quantified as part of the pesticide registration process. GLP 5 batch analysis involves the testing of five production batches of an agrochemical active to identify and structurally elucidate impurities that are present above a set level.

Once the process impurities above this level are identified, reference standards of each impurity need to be obtained, either by chromatographic separation or custom synthesis and then used in a GLP analysis carried out using validated analytical methods to accurately quantify the presence of the impurities in the five batches of the active.

FB Pharmtech utilises our years of experience in custom synthesis to produce agrochemical impurities for use in GLP 5 batch analysis. Due to the way in which impurities are formed in small amounts from side reactions during the manufacturing process, the synthesis of impurities in larger quantities can often be challenging and complex work. Our dedicated team of chemists have the experience of having worked on many agrochemical impurity synthesis projects, and understand the challenges involved in this work.

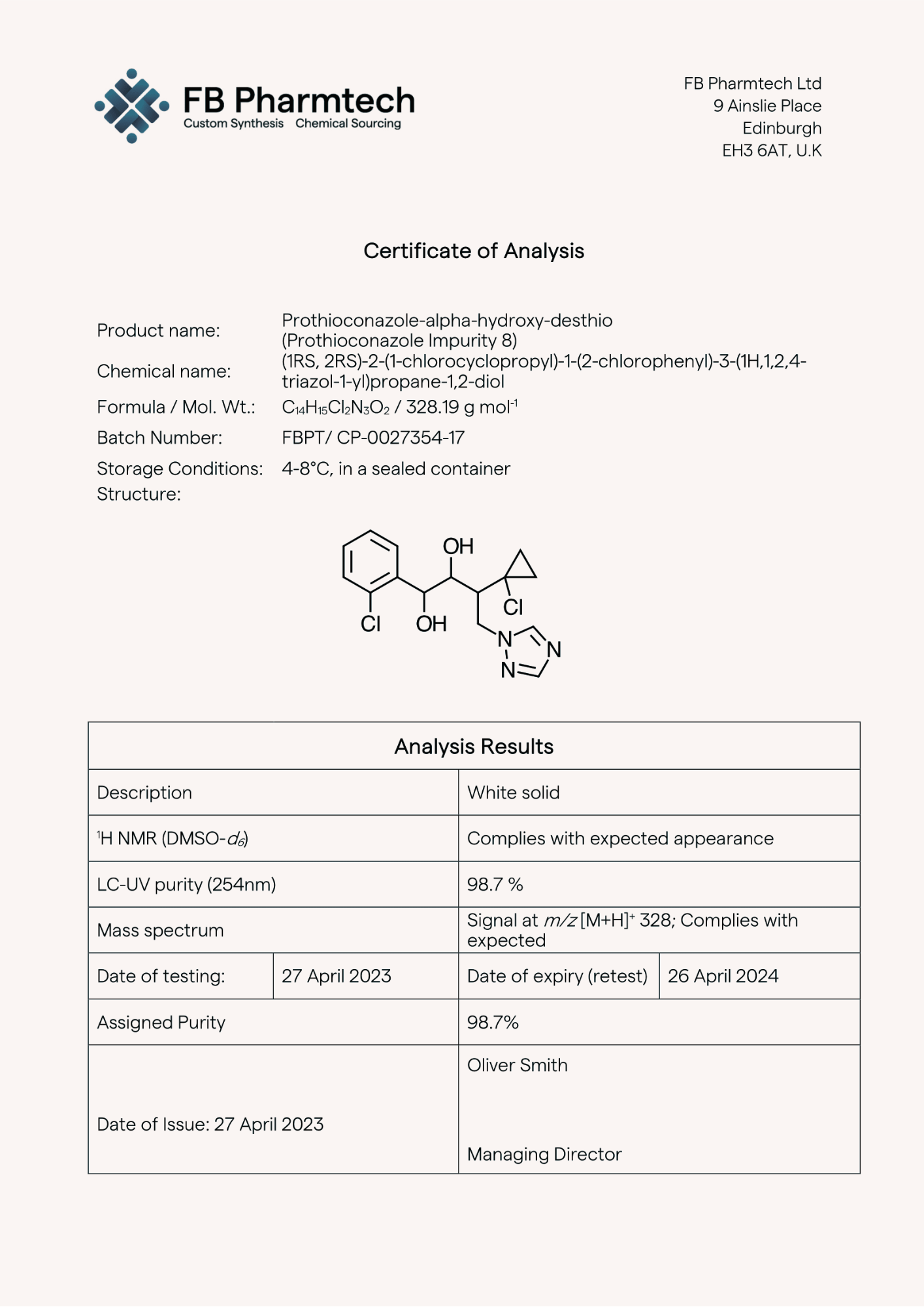

Our impurities come with a full certificate that includes NMR, HPLC/GC, MS & KF, and can include additional analysis techniques based on the customer’s requirement – e.g. elemental analysis, solvent residue, inorganic content.

Agrochemical Metabolite Reference Standards

Agrochemical metabolite reference standards are used in environmental fate, toxicity and residue studies, as part of the pesticide registration process.

These studies are carried out to understand how substances act, degrade and pass through plants, crops and animals, as well as how products arising from the degradation process impact the wider environment. These analytical studies are an essential part of safeguarding human and animal health from the adverse effects of pesticides.

Agrochemical metabolites are formed in living organisms through the actions of enzymes during metabolism. For this reason, the structural changes that take place to form a metabolite are often complex and can be difficult to replicate in a lab setting using conventional chemistry. Our chemists’ experience in this area of synthesis, combined with extensive resources, means they can use innovative chemical approaches to successfully obtain high purity agrochemical metabolite standards.

As with our agrochemical impurity reference standards, all our metabolite standards come with a full COA including analysis by NMR, HPLC, MS.

Case Study

An example of a project where our strength in metabolite custom synthesis can be demonstrated is in the custom synthesis of Prothioconazole des-thio hydroxy metabolites. We first successfully synthesised these materials on a 10g scale.

The chemistry was challenging and yields low, but after extensive process R&D, and optimisation, we were able to successfully synthesise all of these metabolites for our customers, and we have since gone on to repeat the syntheses of these several times for a number of different customers who have been required to use these materials in their ongoing pesticide registration studies.